Introduction

Diamond CSB III-S Series

12 / 16 / 20 / 25 CSB III-S

- Cross travel sub-spindle: Cross travel sub-spindle design. The main and sub spindles can work either one at a time or simultaneously for reduced machining duration. This design brings multi-function front and rear machining.

- Short remnant material: With the optional rough material bushing, the remnant material can be 50mm (depending on the part length).

- Raw material machining: 0.1mm material tolerance can be achieved by using the Rough material bushing.

CNC Swiss Precision Machining(CSBIII-S) Structure

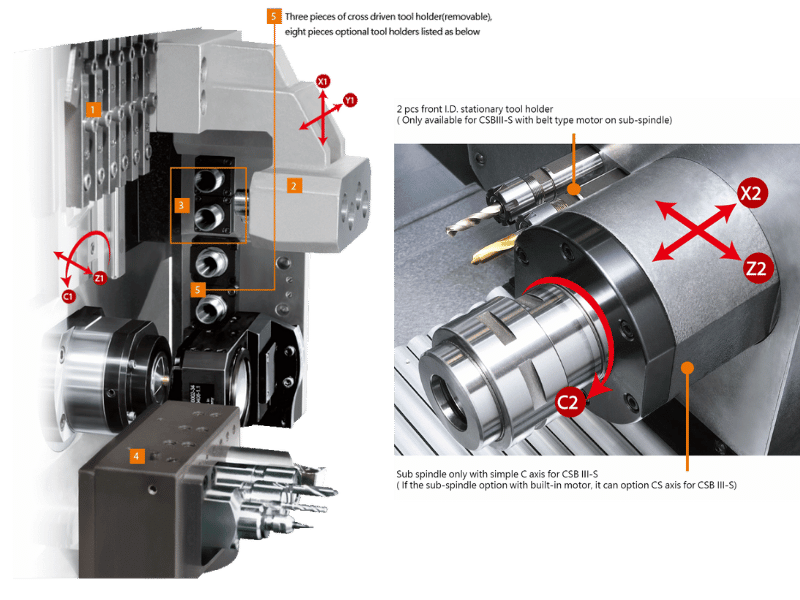

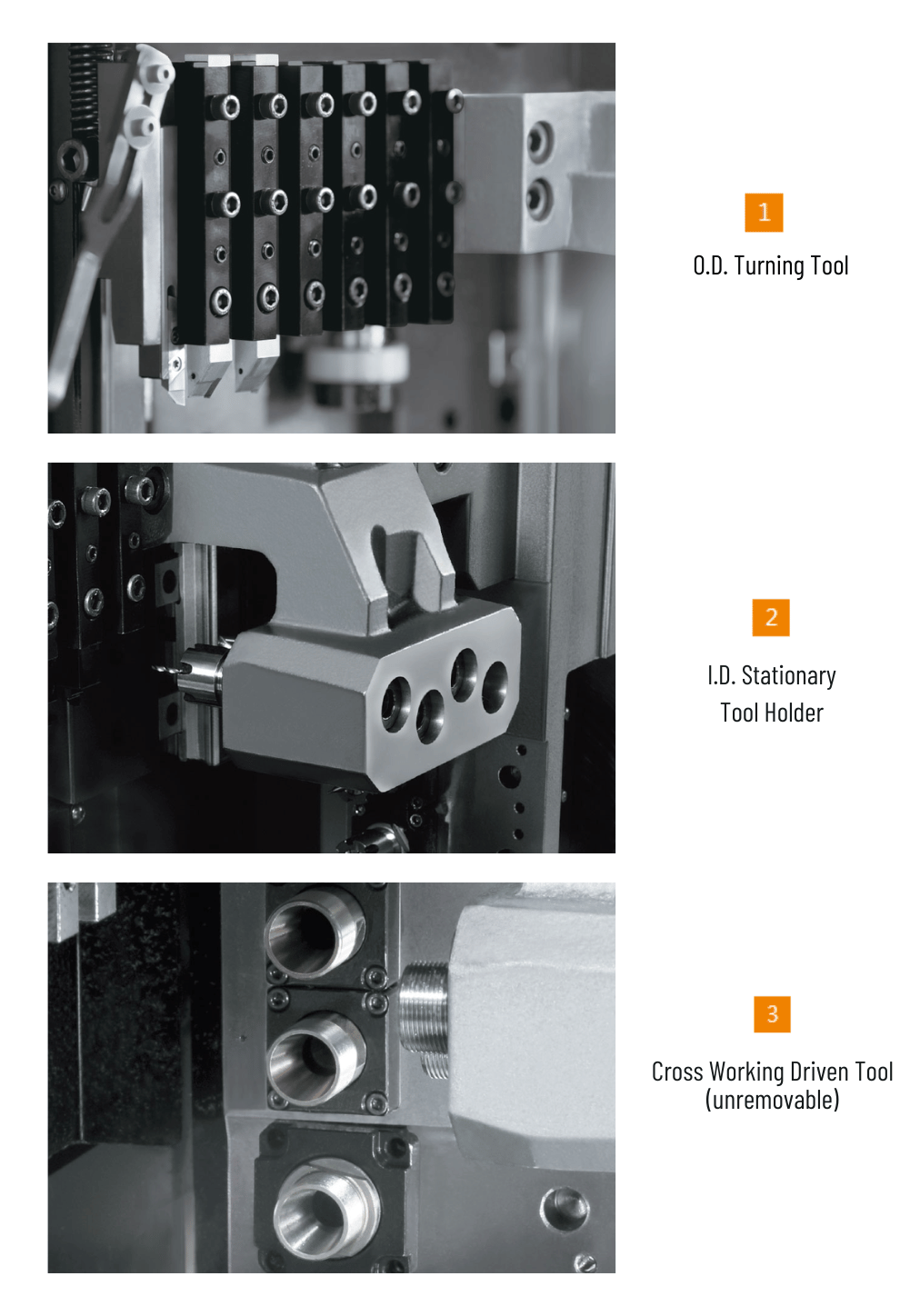

1: O.D. Turning Tool2: I.D. Stationary Tool Holder

3: Cross Working Driven Tool(unremovable)

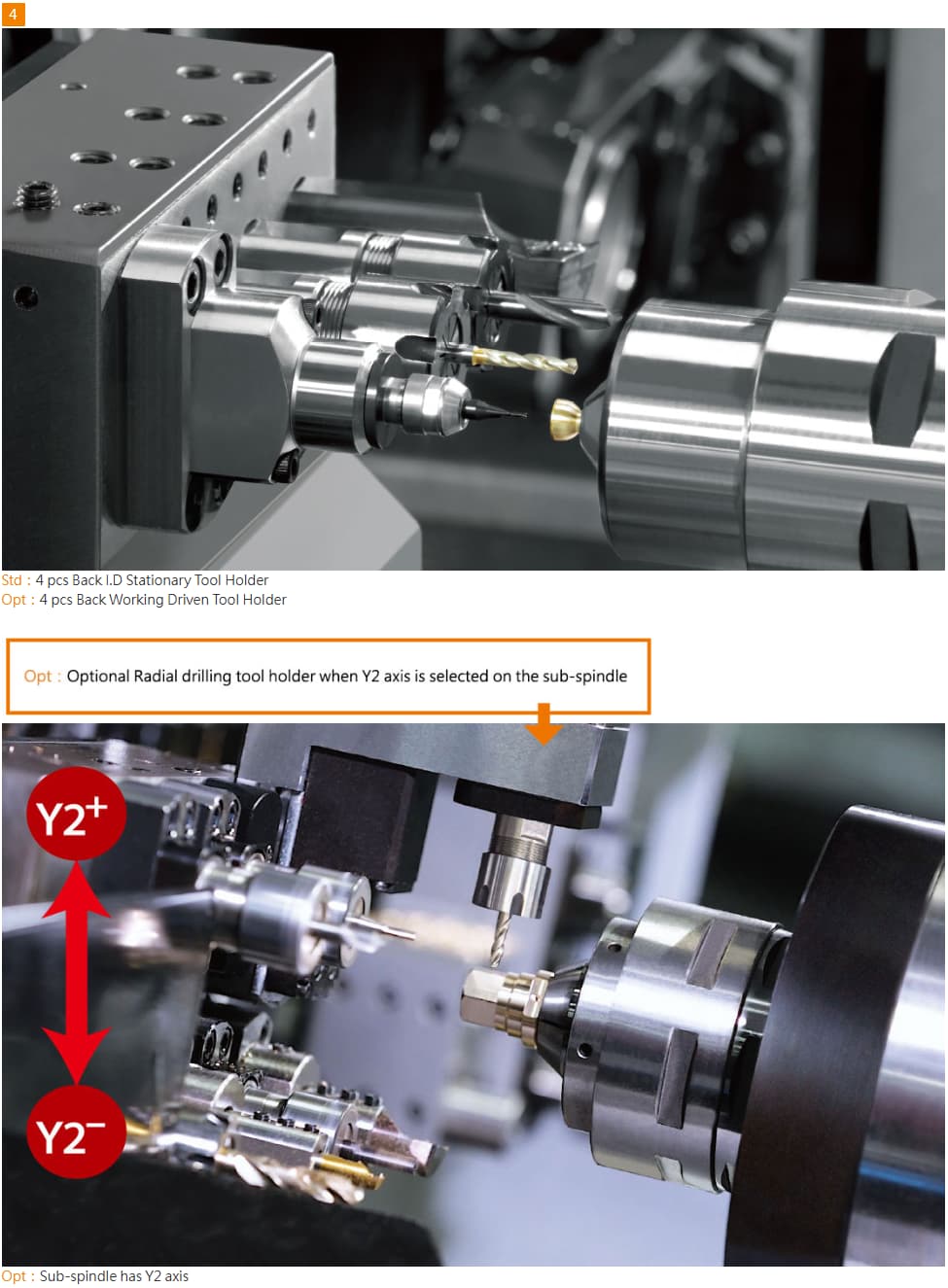

4:

Std:4 pcs Back I.D Stationary Tool Holder

Opt:4 pcs Back Working Driven Tool Holder

Opt:Sub-spindle has Y2 axis

Std:4 pcs Back I.D Stationary Tool Holder

Opt:4 pcs Back Working Driven Tool Holder

Opt:Sub-spindle has Y2 axis

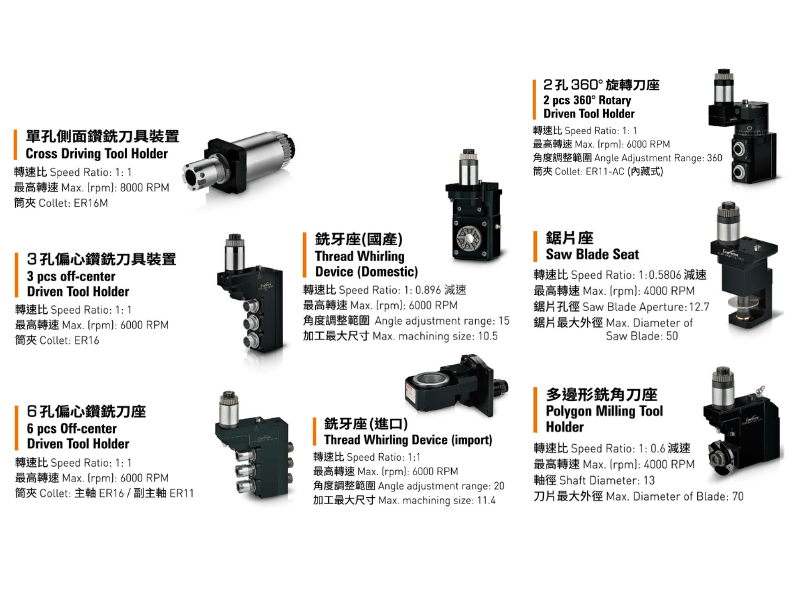

5: Three pieces of cross driven tool holder(removable), eight pieces optional tool holders listed on the right:

Standard Accessories

- Controller: Mitsubishi

- Main Spindle

- Back Spindle

- Working Light

- Coolant System

- Part off Detection Sensor

- Part Catcher

- Live Bushing

- Fixed Bushing (Except 25CSB III-S)

- 6 pcs O.D. Turning Tool Holder

- 4 pcs I.D. Stationary Tool Holder

- 4 pcs Back I.D. Stationary Tool Holder

- 4 pcs Back I.D. Stationary Tool Holder

- 2 pcs+3 pcs Cross Working Driven Tool Holder

Optional Accessories

- Controller: Fanuc

- CS Axis

- Y2 Axis

- Chip Conveyor + Bucket

- 4 pcs Back Working Driven Tool Holder (If choose Y2 axis need to option)

- 2 pcs Front I.D. Stationary Tool Holder (sub-spindle with belt type motor)

Specification

| Items | DIAMOND 12 CSB III-S | DIAMOND 16 CSB III-S | DIAMOND 20 CSB III-S | DIAMOND 25 CSB Ⅲ-S |

|---|---|---|---|---|

| Working Range | ||||

| Max. Machining Dia. | Ø12.7 mm | Ø16.5 mm | Ø20 mm | Ø26 mm |

| Max. Machining Length Per Chucking | 200 mm | 200 mm | 200 mm | 200 mm |

| Max. Drilling Dia. (Main Spindle) | Ø7 mm | Ø10 mm | Ø10 mm | Ø10 mm |

| Max. Drilling Dia. (Sub Spindle) | Ø7mm | Ø7mm | Ø7mm | Ø7mm |

| Max. Tapping Dia. (Main Spindle) | M6 | M8 | M8 | M8 |

| Max.Tapping Dia. (Sub Spindle) | M6 | M6 | M6 | M6 |

| O.D. Tooling | ||||

| Number of Tools | 6 | 6 | 6 | 6 |

| Dimension | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 × 120 |

| I.D. Tooling | ||||

| Number of Tools | 4 | 4 | 4 | 4 |

| Dimension | 10mm (ER16) | 10mm (ER16) | 10 mm (ER16) | 10 mm (ER16) |

| Cross Working Driven Tooling | ||||

| Number of Tools | 2+3 | 2+3 | 2+3 | 2+3 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) |

| Cross Spindle Speed | 200~6,000rpm | 200-6000 r.p.m. | 200~6,000rpm | 200-6000 r.p.m. |

| Back I.D. Tooling | ||||

| Number of Tools | 4+4 | 4+4 | 4+4 | 4+4 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) |

| Back Working Driven Tooling (Option) | ||||

| Number of Tools | 4 | 4 | 4 | 4 |

| Dimension | 10mm (ER16) | 10mm (ER16) | 10mm (ER16) | 10mm (ER16) |

| Speed | 6,000rpm | 6,000rpm | 6,000rpm | 6,000rpm |

| Spindle | ||||

| Spindle Hole Dia. | Ø13 mm | ø17 mm | ø22 mm | ø27 mm |

| Spindle Speed | 200~8,000rpm | 200~8,000rpm | 200~8,000rpm | 200~8,000rpm |

| Main Spindle Indexing Angle | C axis | C axis | C axis | C axis |

| Back Spindle | ||||

| Back Spindle Hole Dia. | Ø13 mm | ø17 mm | ø22 mm | ø27 mm |

| Back Spindle Speed | 200~5,000 rpm | 200~5,000 rpm | 200~5,000 rpm | 200~5,000 rpm |

| (Option built-in motor) | 200~8,000rpm | 200~8,000rpm | 200~8,000rpm | 200~8,000rpm |

| Max. length for front ejection | 50 mm | 50 mm | 50 mm | 50 mm |

| Sub Spindle Indexing Angle | C axis | C axis | C axis | C axis |

| Rapid Traverse | ||||

| X1, Y1, Z1, X2, Z2 | 30 m/min | 30 m/min | 30 m/min | 30 m/min |

| Motors | ||||

| Built-in Spindle Motor | 2.2 kW | 2.2 kW | 3.7 kW | 3.7 kW |

| Back Spindle Motor | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW |

| (Option built-in motor) | 2.2 kW | 2.2 kW | 3.7 kW | 3.7 kW |

| X1, Y1, Z1, X2, Z2 Axes Motor | 1 kW | 1 kW | 1 kW | 1 kW |

| Y2 Axis Motor (Option) | 1 kW | 1 kW | 1 kW | 1 kW |

| Coolant Pump Motor | 1 HP | 1 HP | 1 HP | 1 HP |

| Lubrication Motor | 4 W | 4 W | 4 W | 4 W |

| Cross Driven Tool Motor | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW |

| Back Driven Tool Motor (Option) | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| Y2 Axis with Back Driven Tool Motor (Option) | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW |

| Machine Dimensions | ||||

| Center Height | 890 mm | 890 mm | 890 mm | 890 mm |

| Weight | 1,920 kg | 2,070 kg | 2,120 kg | 2,170 kg |

| Optional Y2 Axis | 2,300 kg | 2,450 kg | 2,500 kg | 2,550 kg |

| Machine Dimension | 2,440 x 1,430 x 1,650 mm | 2,440 x 1,430 x 1,650 mm | 2,440 x 1,430 x 1,650 mm | 2,440 x 1,430 x 1,650 mm |

| (Option Y2 Axis) | 2,690 x 1,495 x 1,890 mm | 2,690 x 1,495 x 1,890 mm | 2,690 x 1,495 x 1,890 mm | 2,690 x 1,495 x 1,890 mm |

| Air Pressure | ||||

| Air Pressure | 5kg/cm | 5kg/cm | 5kg/cm | 5 kg/cm |

| Air Supply | 10 L/min | 10 L/min | 10 L/min | 10 L/min |

* We reserve the rights to change the design without any prior notification.