Introduction

Revolutionize your machining operations with our Automatic Lathe Machines. Engineered for top-tier precision and efficiency, these machines are designed to tackle complex tasks effortlessly. Their automated capabilities eliminate manual errors and increase throughput, making them ideal for any high-volume, high-precision industry. User-friendly and durable, our Automatic Lathe Machines offer a robust and efficient solution for your manufacturing needs.

Specification

| Items | DIAMOND 12 | DIAMOND 12CS | Diamond 20CS | Diamond 20CSB |

|---|

| Working Range |

|---|

| Max. Turning Dia. | Ø12.7 mm | Ø12.7 mm | Ø16.5 mm | Ø16.5 mm |

| Max. maching length per chucking | 145 mm | 145 mm | 145 mm | 145 mm |

| Max. Drilling Dia. | Ø7 mm | Ø7 mm | Ø10 mm | Ø10 mm |

| Max. Tapping Dia | M6 | M6 | M8 | M8 |

| O.D. Tooling |

|---|

| Number of Tools | 6 | 6 | 6 | 6 |

| Dimension | □10 ×10 ×100 | □10 ×10 ×100 | □10 ×10 ×100 | □10 ×10 ×100 |

| I.D. Tooling |

|---|

| Number of Tools | 4 | 4 | 4 | 4 |

| Dimension | 7 mm (ER11) | 7 mm (ER11) | 10mm (ER16) | 10mm (ER16) |

| Cross Working Driven Tooling |

|---|

| Number of Tools | - | 4 | - | 4 |

| Dimension | - | 7 mm (ER11) | - | 10 mm (ER16) |

| Speed | - | 200~3000 rpm | - | 200~3000 rpm |

| Front Working Driven Tooling |

|---|

| Number of Tools | - | 3 | - | 3 |

| Dimension | - | 7mm (ER11) | - | 10 mm (ER16) |

| Speed | - | 200~3000rpm | - | 200~3000 rpm |

| Main Spindle |

|---|

| Spindle hole dia. | Ø13 mm | Ø13 mm | Ø17 mm | Ø17 mm |

| Spindle Speed | 200- 8,000 r.p.m. | 200- 8,000 r.p.m. | 200- 8,000 r.p.m. | 200- 8,000 r.p.m. |

| Spindle indexing angle | - | C axis (opt. CS axis 0.01° indexing) | - | C axis (opt. CS axis 0.01° indexing) |

| Rapid Traverse |

|---|

| X1, Y1, Z1 axes | 30 M | 30 M | 30 M | 30 M |

| Motors |

|---|

| Main spindle motor | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW |

| X1, Y1, Z1 axes motor | 1 kW | 1 kW | 1 kW | 1 kW |

| Coolant Pump | 1/4 HP | 1/4 HP | 1/4 HP | 1/4 HP |

| Lubrication | 4 w | 4 w | 4 w | 4 w |

| Driven tools motor | - | 1kW | - | 1 kW |

| Machine Dimensions |

|---|

| Center Height | 1050 mm | 1050 mm | 1050 mm | 1050 mm |

| Weight | 1188 kg | 1208 kg | 1220 kg | 1240 kg |

| Machine Dimension | 1200 x 900 x 1750 mm | 1200 x 900 x 1750 mm | 1200 x 900 x 1750 mm | 1200 x 900 x 1750 mm |

| Air Pressure |

|---|

| Air Pressure | 5kg/cm | 5kg/cm | 5kg/cm | 5 kg/cm |

| Air Supply | 10 L/min | 10 L/min | 10 L/min | 10 L/min |

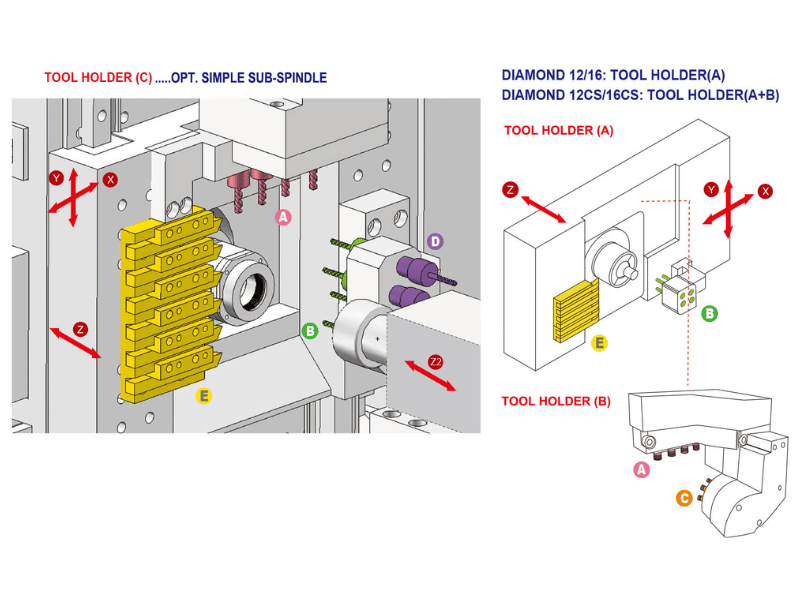

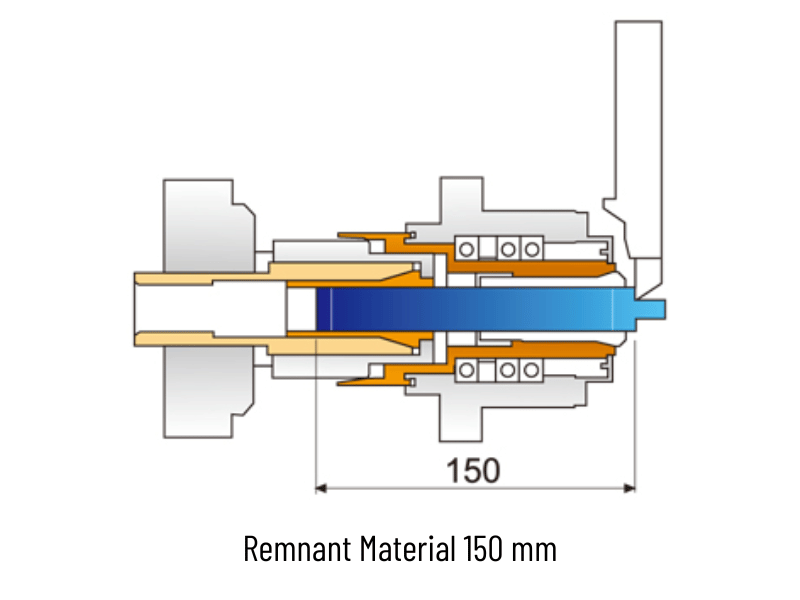

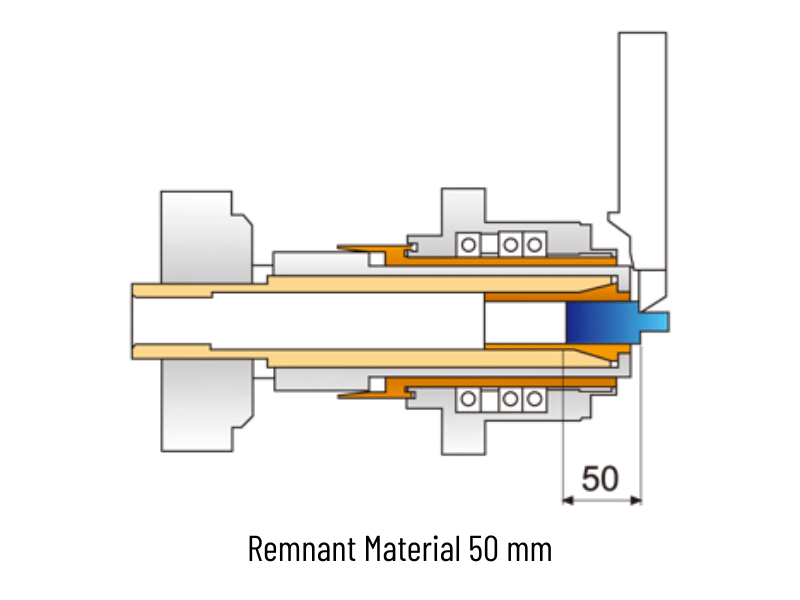

| OPTIONAL-Simple Sub-spindle(Rear Clamping Device) |

|---|

| Simple sub-spindle motor | 1 kW | 1 kW | 1 kW | 1 kW |

| Simple sub-spindle speed | 3000 rpm | 3000 rpm | 3000 rpm | 3000 rpm |

| Z2 axis motor | 1 kW | 1 kW | 1 kW | 1 kW |

| Z2 axis rapid traverse | 18 M | 18 M | 18 M | 18 M |

| Number of back I.D Tools | 4 | 4 | 4 | 4 |

| Dimension of back I.D Tools | 7 mm (ER11) | 7 mm (ER11) | 10 mm (ER16) | 10 mm (ER16) |

| Machine weight | 1350 kg | 1370 kg | 1390 kg | 1410 kg |

| Dimension | 1882 x 1246 x 1860 mm | 1882 x 1246 x 1860 mm | 1882 x 1246 x 1860 mm | 1882 x 1246 x 1860 mm |

* We reserve the rights to change the design without any prior notification.