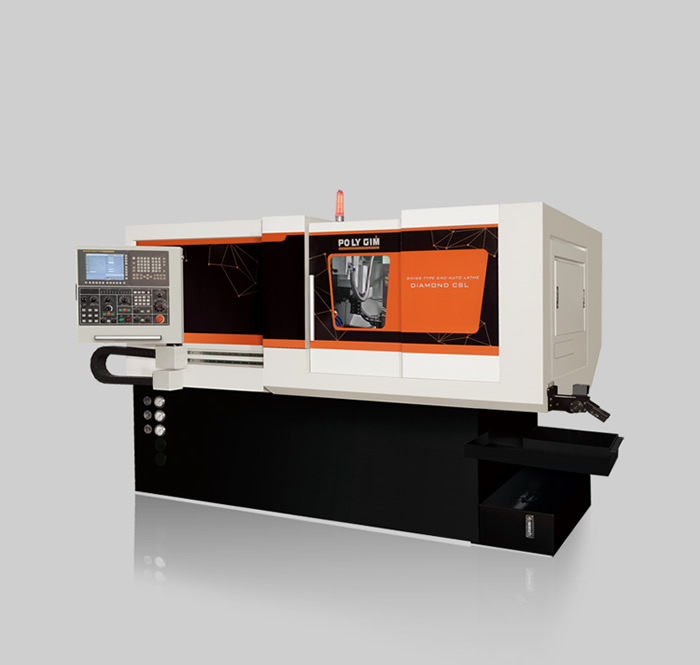

Introduction

Discover the future of precision machining with our Sliding Head Turning solutions. These machines bring together Swiss Type CNC technology and advanced sliding head capabilities for unparalleled accuracy. Ideal for intricate parts and complex geometries, our Sliding Head Turning machines are engineered for high-speed, high-quality output. Elevate your machining process to new heights of efficiency with these cutting-edge systems.

Specification

| Items | 25 CSL | 32 CSL | 42 CSL |

|---|

| Working Range |

|---|

| Max. Turning Dia. | Ø26mm | Ø32mm | Ø42mm |

| Max. maching length per chucking | 250mm | 250mm | 250mm |

| Max. Drilling Dia. | Ø26mm | Ø26mm | Ø26mm |

| Max. Tapping Dia | M16 | M16 | M16 |

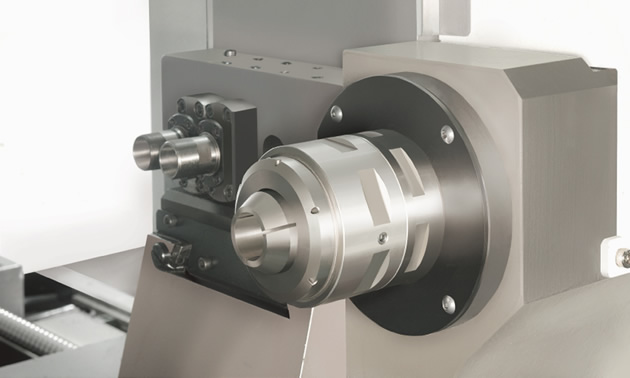

| Tooling System |

|---|

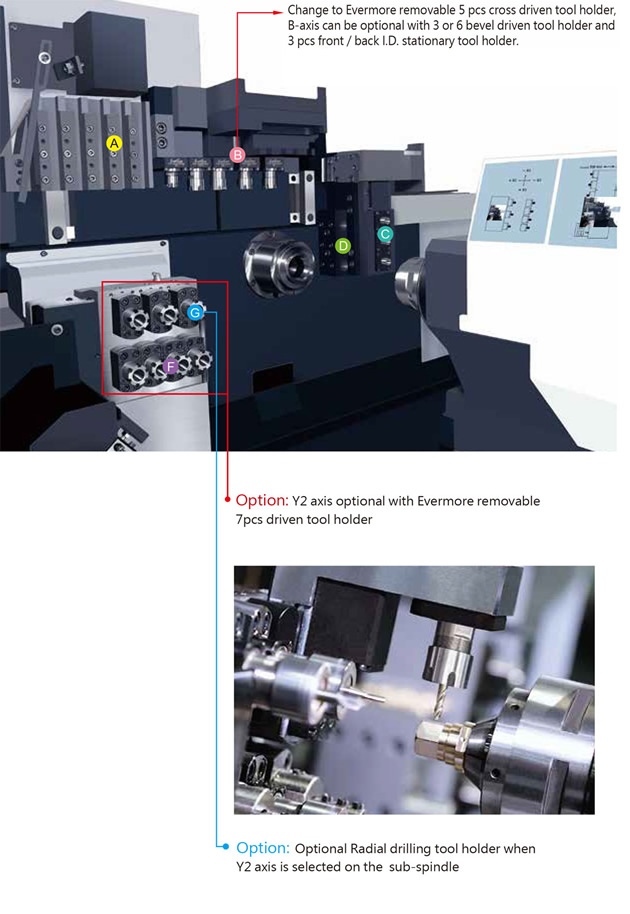

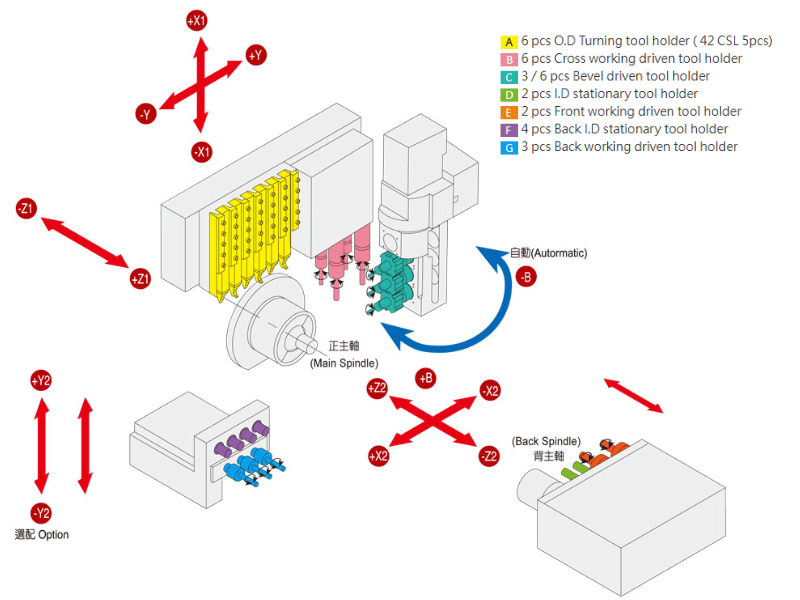

| O.D.Tooling(B axis with 3/6 pcs) | 6 | 6 | 5 |

| O.D.Tooling(B axis with 8 pcs) | 7 | 7 | 6 |

| O.D.Tool Dimension | □16x16x120 | □16x16x120 | □16x16x120 |

| (Front) I.D. Tooling(B axis with 3/6 pcs) | 2 | 2 | 2 |

| (Front) I.D. Tooling(B axis with 8 pcs) | 3 | 3 | 2 |

| Tool Dimension | 13 mm (ER20) | 13 mm (ER20) | 13 mm (ER20) |

| (Back) I.D.Tooling | 4 | 4 | 4 |

| Tool Dimension(B axis with 3 pcs) | 13 mm (ER20) | 13 mm (ER20) | 13 mm (ER20) |

| Cross Tooling | 6 | 6 | 6 |

| Tool Dimension | 13 mm (ER20) | 13 mm (ER20) | 13 mm (ER20) |

| Speed | 200~6000rpm | 200~6000 r.p.m. | 200~6000 r.p.m. |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 3/6 pcs) | 3/6 | 3/6 | 3/6 |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 8 pcs) | 8 | 8 | 8 |

| Tool Dimension(B axis with 3 pcs) | 13mm (ER20) | 13mm (ER20) | 13mm (ER20) |

| Speed | 100~6000rpm | 100~6000rpm | 100~6000rpm |

| (Opt.) Front Drilling Tooling | 2 | 2 | 2 |

| Tool Dimension | 13mm (ER20) | 13mm (ER20) | 13mm (ER20) |

| Speed | 200~6000rpm | 200~6000rpm | 200~6000rpm |

| (Opt.) Back Drilling Tooling | 3 | 3 | 3 |

| Tool Dimension | 13mm (ER20) | 13mm (ER20) | 13mm (ER20) |

| Speed | 100~4000rpm | 100~4000rpm | 100~4000rpm |

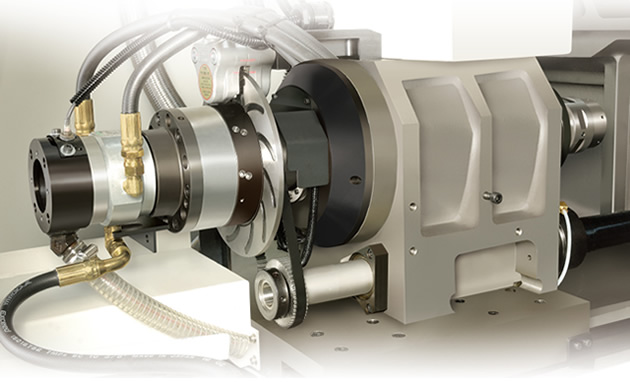

| Spindle |

|---|

| Spindle Hole Dia. | Ø26mm | Ø33mm | Ø42mm |

| Spindle Speed | 200~7000rpm | 200~7000rpm | 200~5000rpm |

| Indexing | C axis | C axis | C axis |

| Back Spindle |

|---|

| Back Spindle Hole Dia. | Ø25mm | Ø33mm | Ø42mm |

| Back Spindle Speed | 200~6000rpm | 200~6000rpm | 200~5000rpm |

| Indexing | 5° | 5° | 5° |

| Max. length for front ejection | 70mm | 70mm | 70mm |

| Max. workpiece projection length from the back spindle | 120mm | 120mm | 120mm |

| Max.Back Drilling Dia. | Ø16mm | Ø16mm | Ø16mm |

| Max. Back Tapping Dia. | M12 | M12 | M12 |

| Rapid Traverse |

|---|

| X1, Z1, Y1, X2, Z2 Axes | 18 or 30 m/min | 18 or 30 m/min | 18 or 30 m/min |

| (Opt.) Y2 Axis | 18 or 30 m/min | 18 or 30 m/min | 18 or 30 m/min |

| Motors |

|---|

| Main Spindle Motor | 3.7/5.5kW | 3.7/5.5kW | 18.5/30kW |

| Back Spindle Motor | 2.2kW | 2.2kW | 2.2kW |

| X1, Z1, Y1, X2, Z2 Axes Motor | 1.2kW | 1.2kW | 1.2kW |

| (Opt.) Y2, B Axes Motor | 0.75kW | 0.75kW | 0.75kW |

| Cross driven spindle Motor | 2.2kW | 2.2kW | 2.2kW |

| (Opt.) Bevel driven spindle Motor(B axis with 3/6 pcs) | 1kW | 1kW | 1kW |

| (Opt.) Bevel driven spindle Motor(B axis with 8 pcs) | 2.2kW | 2.2kW | 2.2kW |

| (Opt.) Back driven spindle Motor | 0.75kW | 0.75kW | 0.75kW |

| (Opt. Y2 Axis) Back driven spindle Motor | 1kW | 1kW | 1kW |

| Coolant Pump | 0.75kW x 2 | 0.75kW x 2 | 0.75kW x 2 |

| Lubrication | 4W x 2 | 4W x 2 | 4W x 2 |

| Machine Dimensions |

|---|

| Center Height | 960mm / 1020mm(a plug-in electrical cabinet) | 960mm / 1020mm(a plug-in electrical cabinet) | 960mm / 1020mm(a plug-in electrical cabinet) |

| Weight(Standard) | 3988 / 4368(Opt. Y2) | 3988 / 4368(Opt. Y2) | 4088 / 4468(Opt. Y2) |

| Weight(a plug-in electrical cabinet) | 4550 / 4930(Opt. Y2) | 4550 / 4930(Opt. Y2) | 4650 / 5030(Opt. Y2) |

| Machine Size(Standard) | 3000x1540x1940 mm | 3000x1540x1940 mm | 3000x1540x1940 mm |

| Machine Size(a plug-in electrical cabinet) | 3220x1800x2005 mm | 3220x1800x2005 mm | 3220x1800x2005 mm |

| Air |

|---|

| Air Pressure | 5kg/cm | 5kg/cm | 5kg/cm |

| Air Supply | 10L/min | 10L/min | 10L/min |

* We reserve the rights to change the design without any prior notification.