CSL 25/32/42

Swiss Type CNC Lathe

Diamond CSL Series

Discover the future of precision machining with our Sliding Head Turning solutions. These machines bring together Swiss Type CNC technology and advanced sliding head capabilities for unparalleled accuracy. Ideal for intricate parts and complex geometries, our Sliding Head Turning machines are engineered for high-speed, high-quality output. Elevate your machining process to new heights of efficiency with these cutting-edge systems.

Machine Features

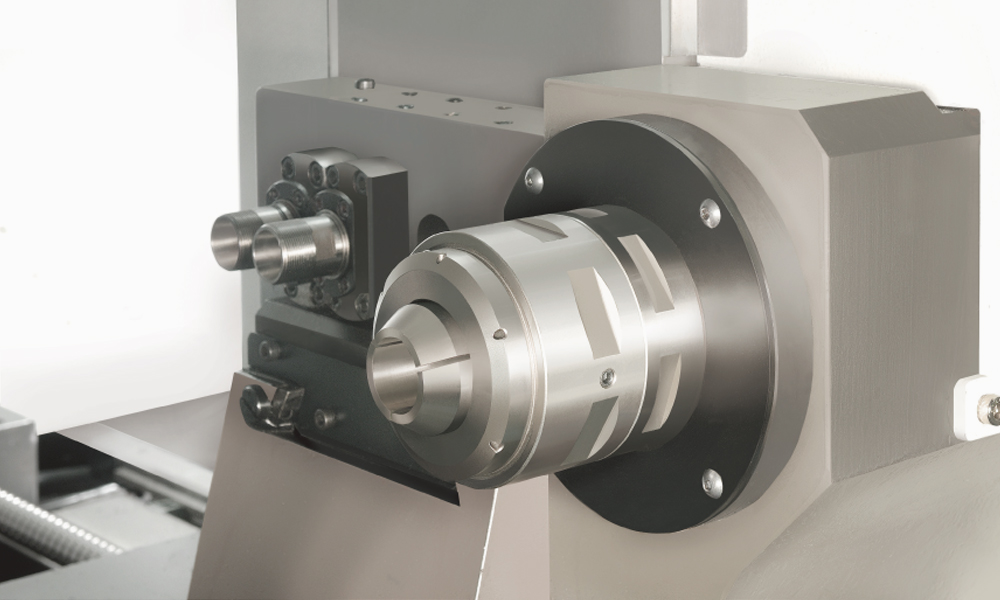

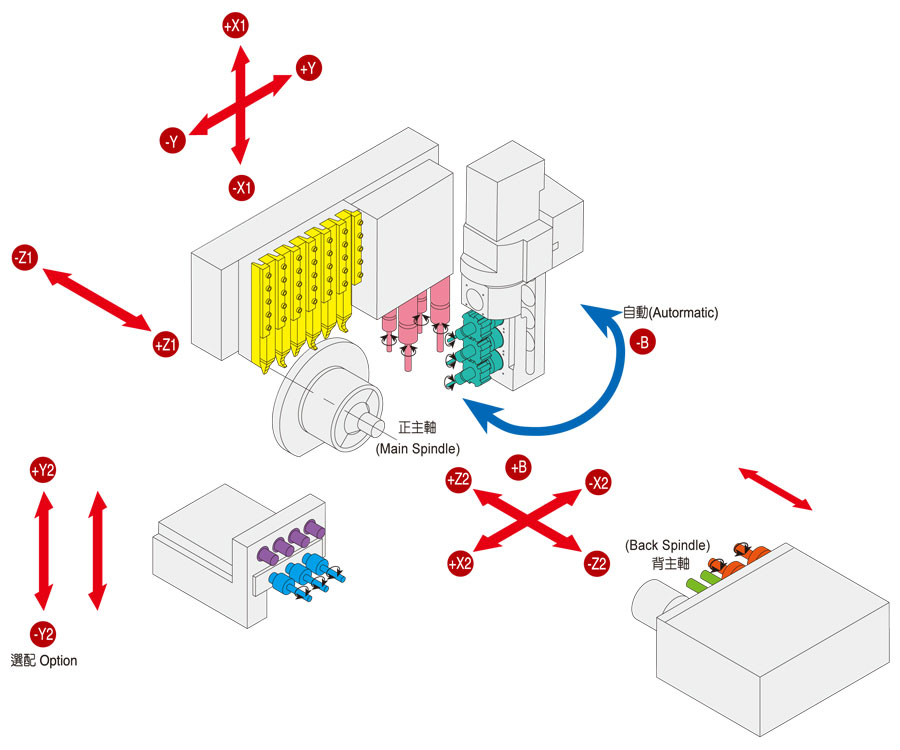

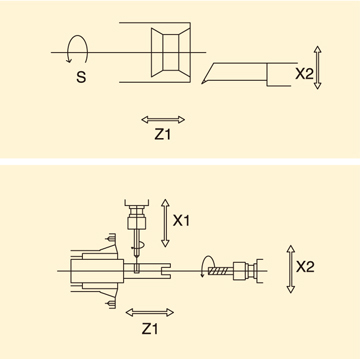

Cross spindle and bevel driven tool holes will help you to do drilling, milling and tapping on cross side and bevel.

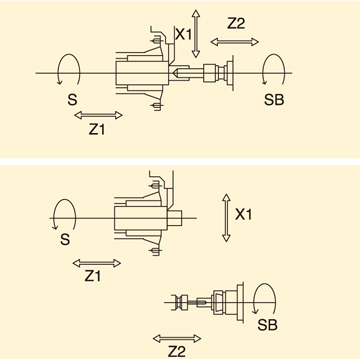

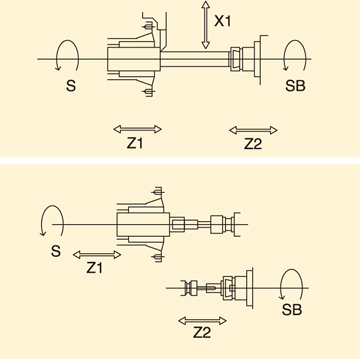

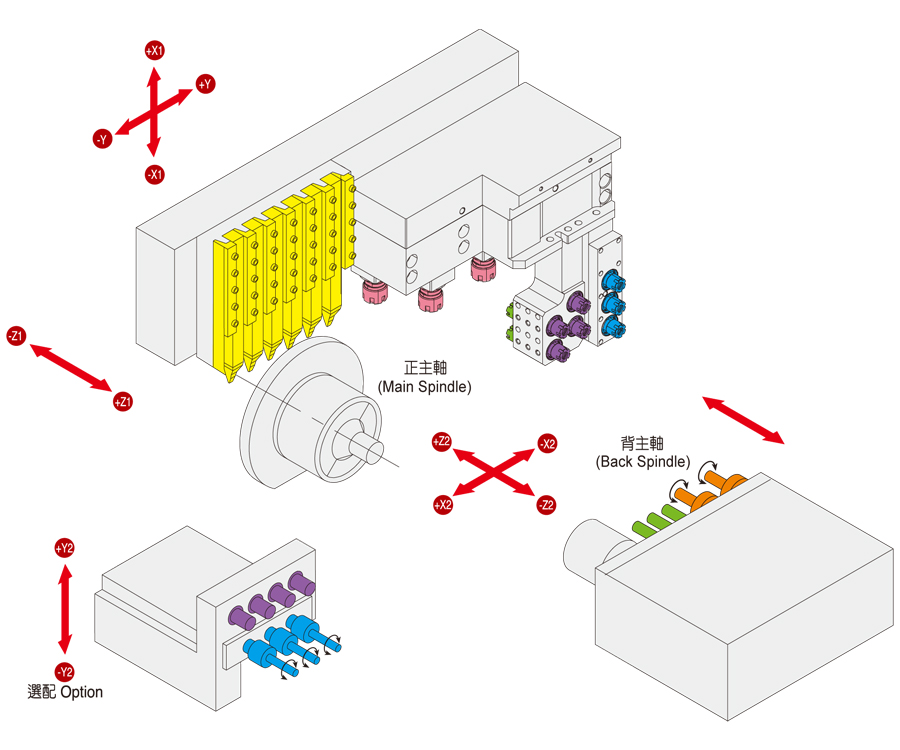

Cross travel sub-spindle design, the main and sub-spindle can work either one at a time or simultaneously for reduced machining duration.

This design bring multi-function front and rear machining.

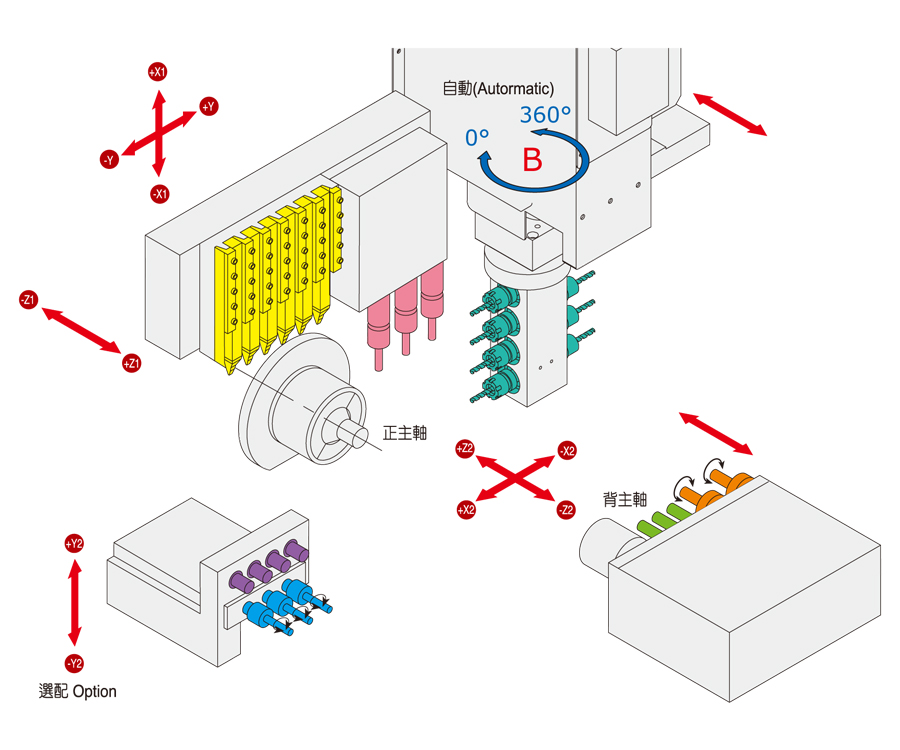

The B-axis bevel driven tool holder can be rotated 360 degrees tofacilitate bevel drilling, milling and tapping with the main and rear spindle.

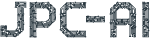

Main spindle is equipped with built-in motor, and the standard is equipped with C axis. A high-analytic CS axis is optional.

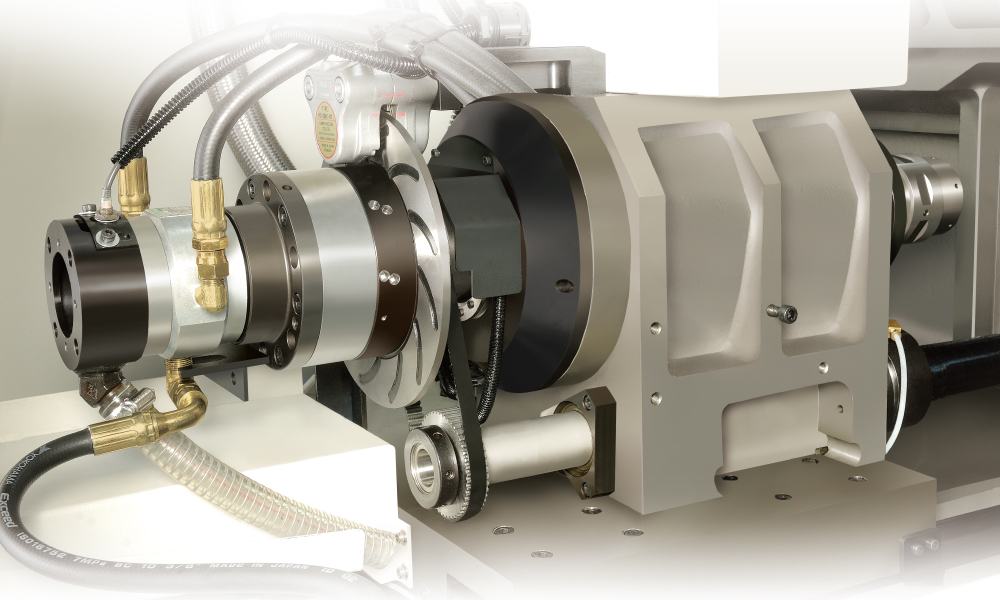

Sub-spindle is equipped with servo motor, and the standard is 5 degree indexing. C-axis is optional.

There are 2 fixed and 2 power drills on the tool holder beside the sub-spindle, which can move forward and backward. It is suitable for deep hole processing.

Examples:

Model: Swiss Type CNC Lathe (Sliding Head Turning) - DIAMOND 25/32/42 CSL

6 pcs O.D Turning tool holder ( 42 CSL 5pcs)

6 pcs O.D Turning tool holder ( 42 CSL 5pcs)

6 pcs Cross working driven tool holder

6 pcs Cross working driven tool holder

3 / 6 pcs Bevel driven tool holder

3 / 6 pcs Bevel driven tool holder

2 pcs I.D stationary tool holder

2 pcs I.D stationary tool holder

2 pcs Front working driven tool holder

2 pcs Front working driven tool holder

4 pcs Back I.D stationary tool holder

4 pcs Back I.D stationary tool holder

3 pcs Back working driven tool holder

3 pcs Back working driven tool holder

- Standard Accessories

Controller : Fanuc 0i –TF PLUS / Fanuc 31i-B (Opt. Y2 axis)

Controller : Fanuc 0i –TF PLUS / Fanuc 31i-B (Opt. Y2 axis) Main spindle C axis orientation

Main spindle C axis orientation Back spindle 5º orientation

Back spindle 5º orientation Working light

Working light Coolant system

Coolant system Part off detective sensor

Part off detective sensor Part catcher

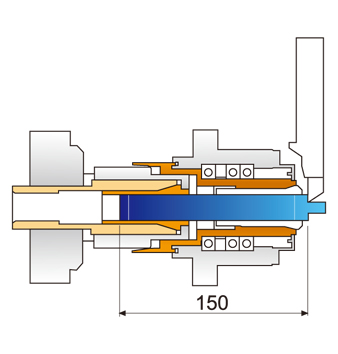

Part catcher Live bushing

Live bushing O.D turning tool holder ----- 5~7pcs

O.D turning tool holder ----- 5~7pcs Front I.D stationary tool holder ----- 2~3pcs

Front I.D stationary tool holder ----- 2~3pcs Back I.D stationary tool holde ----- 4pcs

Back I.D stationary tool holde ----- 4pcs Cross working driven tool holder ----- 6 / 5pcs (with Evermore)

Cross working driven tool holder ----- 6 / 5pcs (with Evermore)

- Option Accessories

Controller : Mitsubishi M80 / Mitsubishi M830 (Opt. Y2 axis)

Controller : Mitsubishi M80 / Mitsubishi M830 (Opt. Y2 axis) Front working driven tool holder ----- 2pcs

Front working driven tool holder ----- 2pcs 360゜b-axis bevel driven tool holder ----- 3 / 6 / 8pcs

360゜b-axis bevel driven tool holder ----- 3 / 6 / 8pcs Back working driven tool holder ----- 3 / 7 pcs (Opt. Evermore)

Back working driven tool holder ----- 3 / 7 pcs (Opt. Evermore) CS axis ( 0.001° orientation-Fanuc / 0.01° orientation-Mitsubishi)

CS axis ( 0.001° orientation-Fanuc / 0.01° orientation-Mitsubishi)- ----- Main spindle

C axis ----- Sub-spindle

C axis ----- Sub-spindle Chip conveyer + Bucket

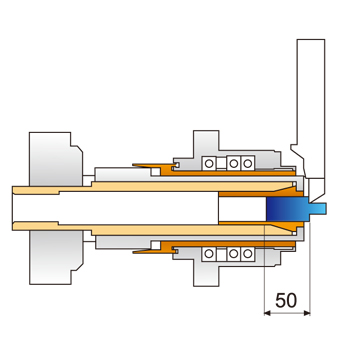

Chip conveyer + Bucket Rough material bushing

Rough material bushing Y2 Axis

Y2 Axis

7 pcs O.D turning tool holder (42CSL 6pcs)

7 pcs O.D turning tool holder (42CSL 6pcs)

6 pcs cross working deiven tool holder

6 pcs cross working deiven tool holder

8 pcs 360° B axis bevel driven tool holder

8 pcs 360° B axis bevel driven tool holder

3 pcs I.D stationary tool holder ( 42CSL 2 pcs)

3 pcs I.D stationary tool holder ( 42CSL 2 pcs)

2 pcs front off-center driven tool holder

2 pcs front off-center driven tool holder

4 pcs back I.D stationary tool holder

4 pcs back I.D stationary tool holder

3 pcs back off-center driven tool holder

3 pcs back off-center driven tool holder

Using Live Bushing with Guide Bush

Remnant Material 150 mm

Using Rough Material Bushing without Guide Bush

Remnant Material 50 mm

Cancel the 8 pcs B-axis bevel driven tool holder and replace a off-center driven tool holder

7 pcs O.D Turning tool holder ( 42 CSL 6pcs)

7 pcs O.D Turning tool holder ( 42 CSL 6pcs)

6 pcs Cross working driven tool holder

6 pcs Cross working driven tool holder

4 pcs + 3 pcs (42 CSL 2pcs) Front I.D stationary tool holder

4 pcs + 3 pcs (42 CSL 2pcs) Front I.D stationary tool holder

3 pcs + 2 pcs Front working driven tool holder

3 pcs + 2 pcs Front working driven tool holder

4 pcs + 4 pcs Back I.D stationary tool holder

4 pcs + 4 pcs Back I.D stationary tool holder

3 pcs + 3 pcs Back working driven tool holder

3 pcs + 3 pcs Back working driven tool holder

- Standard Accessories

Controller : Fanuc 0i –TF PLUS

Controller : Fanuc 0i –TF PLUS Main spindle C axis orientation

Main spindle C axis orientation Back spindle 5º orientation

Back spindle 5º orientation Working light

Working light Coolant system

Coolant system Part off detective sensor

Part off detective sensor Part catcher

Part catcher Live bushing

Live bushing O.D turning tool holder ----- 7pcs (42CSL 6pcs)

O.D turning tool holder ----- 7pcs (42CSL 6pcs) Front I.D stationary tool holder ----- 3pcs (42CSL 2pcs)

Front I.D stationary tool holder ----- 3pcs (42CSL 2pcs) Back I.D stationary tool holder ----- 4pcs

Back I.D stationary tool holder ----- 4pcs Front/Back I.D stationary tool holder ----- 4/4pcs

Front/Back I.D stationary tool holder ----- 4/4pcs Front/Back working driven tool holde ----- 3/3pcs

Front/Back working driven tool holde ----- 3/3pcs Cross working driven tool holder ----- 6 or 5pcs(with Evermore)

Cross working driven tool holder ----- 6 or 5pcs(with Evermore)

- Option Accessories

Controller : Mitsubishi M80

Controller : Mitsubishi M80 Front working driven tool holder ----- 2pcs

Front working driven tool holder ----- 2pcs Back working driven tool holder ----- 3 / 7pcs(Opt. Evermore)

Back working driven tool holder ----- 3 / 7pcs(Opt. Evermore) CS axis ( 0.001° orientation-Fanuc / 0.01° orientation-Mitsubishi)

CS axis ( 0.001° orientation-Fanuc / 0.01° orientation-Mitsubishi)- ----- Main spindle

C axis ----- Sub-spindle

C axis ----- Sub-spindle Chip conveyer + Bucket

Chip conveyer + Bucket Rough material bushing

Rough material bushing Y2 Axis

Y2 Axis

Video

CSL B Axis Machine (Swiss Type CNC Lathe / Sliding Head Turning)

Machine Specifications:

| Items | 25 CSL | |

|---|---|---|

| Working Range | Max. Turning Dia. | Ø26mm |

| Max. maching length per chucking | 250mm | |

| Max. Drilling Dia. | Ø26mm | |

| Max. Tapping Dia | M16 | |

| Tooling System | O.D.Tooling(B axis with 3/6 pcs) | 6 |

| O.D.Tooling(B axis with 8 pcs) | 7 | |

| O.D.Tool Dimension | □16x16x120 | |

| (Front) I.D. Tooling(B axis with 3/6 pcs) | 2 | |

| (Front) I.D. Tooling(B axis with 8 pcs) | 3 | |

| Tool Dimension | 13 mm (ER20) | |

| (Back) I.D.Tooling | 4 | |

| Tool Dimension | 13 mm (ER20) | |

| Cross Tooling | 6 | |

| Tool Dimension | 13 mm (ER20) | |

| Speed | 200~6000 r.p.m. | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 3/6 pcs) | 3/6 | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 8 pcs) | 8 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~6000rpm | |

| (Opt.) Front Drilling Tooling | 2 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 200~6000rpm | |

| (Opt.) Back Drilling Tooling | 3 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~4000rpm | |

| Spindle | Spindle Hole Dia. | Ø26mm |

| Spindle Speed | 200~7000rpm | |

| Indexing | C axis | |

| Back Spindle | Back Spindle Hole Dia. | Ø25mm |

| Back Spindle Speed | 200~6000rpm | |

| Indexing | 5° | |

| Max. length for front ejection | 70mm | |

| Max. workpiece projection length from the back spindle | 120mm | |

| Max.Back Drilling Dia. | Ø16mm | |

| Max. Back Tapping Dia. | M12 | |

| Rapid Traverse | X1, Z1, Y1, X2, Z2 Axes | 18 or 30 m/min |

| (Opt.) Y2 Axis | 18 or 30 m/min | |

| Motors | Main Spindle Motor | 3.7/5.5kW |

| Back Spindle Motor | 2.2kW | |

| X1, Z1, Y1, X2, Z2 Axes Motor | 1.2kW | |

| (Opt.) Y2, B Axes Motor | 0.75kW | |

| Cross driven spindle Motor | 2.2kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 3/6 pcs) | 1kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 8 pcs) | 2.2kW | |

| (Opt.) Back driven spindle Motor | 0.75kW | |

| (Opt. Y2 Axis) Back driven spindle Motor | 1kW | |

| Coolant Pump | 0.75kw x 2 | |

| Lubrication | 4w x 2 | |

| Machine Dimensions | Center Height | 960mm / 1020mm(a plug-in electrical cabinet) |

| Weight(Standard) | 3988 / 4368(Opt. Y2) | |

| Weight(a plug-in electrical cabinet) | 4550 / 4930(Opt. Y2) | |

| Machine Size(Standard) | 3000x1540x1940 mm | |

| Machine Size(a plug-in electrical cabinet) | 3220x1800x2005 mm | |

| Air | Air Pressure | 5kg/cm |

| Air Supply | 10L/min | |

| Items | 32 CSL | |

|---|---|---|

| Working Range | Max. Turning Dia. | Ø32mm |

| Max. maching length per chucking | 250mm | |

| Max. Drilling Dia. | Ø26mm | |

| Max. Tapping Dia | M16 | |

| Tooling System | O.D.Tooling(B axis with 3/6 pcs) | 6 |

| O.D.Tooling(B axis with 8 pcs) | 7 | |

| O.D.Tool Dimension | □16x16x120 | |

| (Front) I.D. Tooling(B axis with 3/6 pcs) | 2 | |

| (Front) I.D. Tooling(B axis with 8 pcs) | 3 | |

| Tool Dimension | 13 mm (ER20) | |

| (Back) I.D.Tooling | 4 | |

| Tool Dimension | 13 mm (ER20) | |

| Cross Tooling | 6 | |

| Tool Dimension | 13 mm (ER20) | |

| Speed | 200~6000 r.p.m. | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 3/6 pcs) | 3/6 | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 8 pcs) | 8 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~6000rpm | |

| (Opt.) Front Drilling Tooling | 2 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 200~6000rpm | |

| (Opt.) Back Drilling Tooling | 3 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~4000rpm | |

| Spindle | Spindle Hole Dia. | Ø33mm |

| Spindle Speed | 200~7000rpm | |

| Indexing | C axis | |

| Back Spindle | Back Spindle Hole Dia. | Ø33mm |

| Back Spindle Speed | 200~6000rpm | |

| Indexing | 5° | |

| Max. length for front ejection | 70mm | |

| Max. workpiece projection length from the back spindle | 120mm | |

| Max.Back Drilling Dia. | Ø16mm | |

| Max. Back Tapping Dia. | M12 | |

| Rapid Traverse | X1, Z1, Y1, X2, Z2 Axes | 18 or 30 m/min |

| (Opt.) Y2 Axis | 18 or 30 m/min | |

| Motors | Main Spindle Motor | 3.7/5.5kW |

| Back Spindle Motor | 2.2kW | |

| X1, Z1, Y1, X2, Z2 Axes Motor | 1.2kW | |

| (Opt.) Y2, B Axes Motor | 0.75kW | |

| Cross driven spindle Motor | 2.2kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 3/6 pcs) | 1kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 8 pcs) | 2.2kW | |

| (Opt.) Back driven spindle Motor | 0.75kW | |

| (Opt. Y2 Axis) Back driven spindle Motor | 1kW | |

| Coolant Pump | 0.75kw x 2 | |

| Lubrication | 4w x 2 | |

| Machine Dimensions | Center Height | 960mm / 1020mm(a plug-in electrical cabinet) |

| Weight(Standard) | 3988 / 4368(Opt. Y2) | |

| Weight(a plug-in electrical cabinet) | 4550 / 4930(Opt. Y2) | |

| Machine Size(Standard) | 3000x1540x1940 mm | |

| Machine Size(a plug-in electrical cabinet) | 3220x1800x2005 mm | |

| Air | Air Pressure | 5kg/cm |

| Air Supply | 10L/min | |

| Items | 42 CSL | |

|---|---|---|

| Working Range | Max. Turning Dia. | Ø42mm |

| Max. maching length per chucking | 250mm | |

| Max. Drilling Dia. | Ø26mm | |

| Max. Tapping Dia | M16 | |

| Tooling System | O.D.Tooling(B axis with 3/6 pcs) | 5 |

| O.D.Tooling(B axis with 8 pcs) | 6 | |

| O.D.Tool Dimension | □16x16x120 | |

| (Front) I.D. Tooling(B axis with 3/6 pcs) | 2 | |

| (Front) I.D. Tooling(B axis with 8 pcs) | 2 | |

| Tool Dimension | 13 mm (ER20) | |

| (Back) I.D.Tooling | 4 | |

| Tool Dimension | 13 mm (ER20) | |

| Cross Tooling | 6 | |

| Tool Dimension | 13 mm (ER20) | |

| Speed | 200~6000 r.p.m. | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 3/6 pcs) | 3/6 | |

| (Opt.) Bevel Drill / Mill Tooling(B axis with 8 pcs) | 8 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~6000rpm | |

| (Opt.) Front Drilling Tooling | 2 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 200~6000rpm | |

| (Opt.) Back Drilling Tooling | 3 | |

| Tool Dimension | 13mm (ER20) | |

| Speed | 100~4000rpm | |

| Spindle | Spindle Hole Dia. | Ø42mm |

| Spindle Speed | 200~5000rpm | |

| Indexing | C axis | |

| Back Spindle | Back Spindle Hole Dia. | Ø42mm |

| Back Spindle Speed | 200~5000rpm | |

| Indexing | 5° | |

| Max. length for front ejection | 70mm | |

| Max. workpiece projection length from the back spindle | 120mm | |

| Max.Back Drilling Dia. | Ø16mm | |

| Max. Back Tapping Dia. | M12 | |

| Rapid Traverse | X1, Z1, Y1, X2, Z2 Axes | 18 or 30 m/min |

| (Opt.) Y2 Axis | 18 or 30 m/min | |

| Motors | Main Spindle Motor | 18.5/30kW |

| Back Spindle Motor | 2.2kW | |

| X1, Z1, Y1, X2, Z2 Axes Motor | 1.2kW | |

| (Opt.) Y2, B Axes Motor | 0.75kW | |

| Cross driven spindle Motor | 2.2kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 3/6 pcs) | 1kW | |

| (Opt.) Bevel driven spindle Motor(B axis with 8 pcs) | 2.2kW | |

| (Opt.) Back driven spindle Motor | 0.75kW | |

| (Opt. Y2 Axis) Back driven spindle Motor | 1kW | |

| Coolant Pump | 0.75kw x 2 | |

| Lubrication | 4w x 2 | |

| Machine Dimensions | Center Height | 960mm / 1020mm(a plug-in electrical cabinet) |

| Weight(Standard) | 4088 / 4468(Opt. Y2) | |

| Weight(a plug-in electrical cabinet) | 4650 / 5030(Opt. Y2) | |

| Machine Size(Standard) | 3000x1540x1940 mm | |

| Machine Size(a plug-in electrical cabinet) | 3220x1800x2005 mm | |

| Air | Air Pressure | 5kg/cm |

| Air Supply | 10L/min | |