CSBIV Series

Swiss Type CNC Lathe

Machine Features:

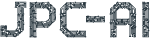

Cross travel sub-spindle :

Cross travel sub-spindle design. The main and sub spindles can work either one at a time or simultaneously for reduced machining duration. This design brings multi-function front and rear machining.

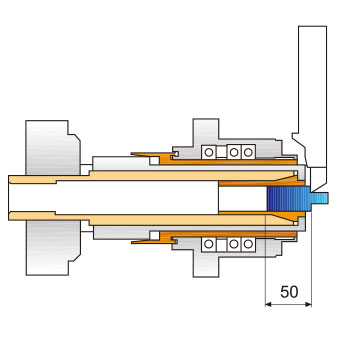

Short remnant material :

With the optional rough material bushing, the remnant material can be 50mm (depending on the part length).

Raw material machining :

0.1mm material tolerance can be achieved by using the Rough material bushing.

The main / sub-spindle are equipped with built-in motor, standard with C axis orientation, and optional high-analysis CS axis.

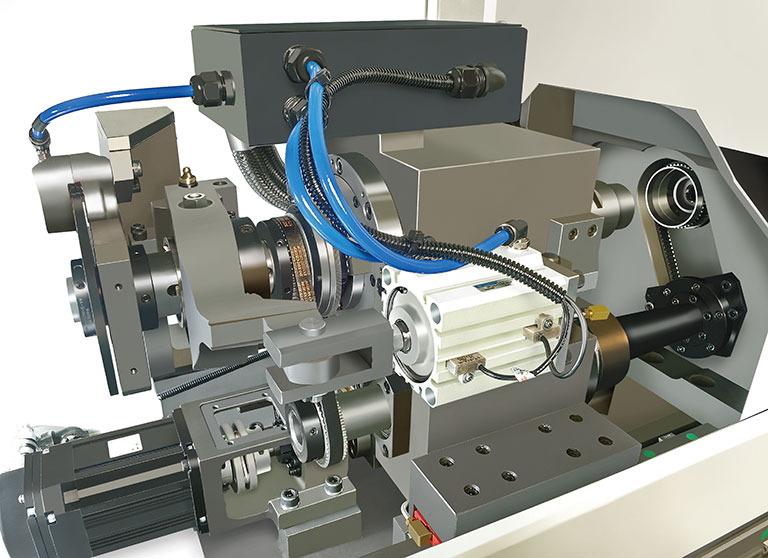

Examples:

4 pcs cross working driven tool holder

4 pcs cross working driven tool holder

4 pcs I.D. stationary tool holder

4 pcs I.D. stationary tool holder

3 pcs front working driven tool holder (opt.)

3 pcs front working driven tool holder (opt.)

4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary tool holder

6 pcs O.D. turning tool holder

6 pcs O.D. turning tool holder

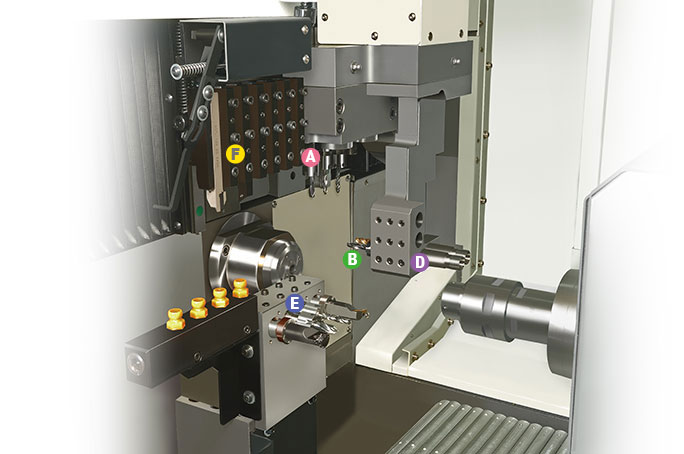

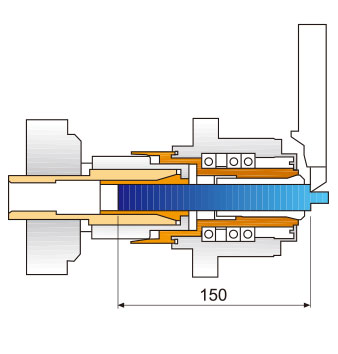

Using Live Bushing with Guide Bush

Remnant Material 150 mm

Using Rough Material Bushing without Guide Bush

Remnant Material 50 mm

Standard Accessories:

Main spindle C axis orientation

Main spindle C axis orientation Sub-spindle C axis orientation

Sub-spindle C axis orientation Working light

Working light Coolant system

Coolant system Part off detective sensor

Part off detective sensor Live bushing

Live bushing

Part catcher

Part catcher 6 pcs O.D. turning tool holder

6 pcs O.D. turning tool holder 4 pcs front I.D. stationary tool holder

4 pcs front I.D. stationary tool holder 4 pcs cross working driven tool holder

4 pcs cross working driven tool holder 4 pcs back I.D stationary tool holder

4 pcs back I.D stationary tool holder

Optional Accessories:

3 pcs front working driven tool holder

3 pcs front working driven tool holder Main & sub-spindle CS axis orientation (0.01°orientation)

Main & sub-spindle CS axis orientation (0.01°orientation) Fixed bushing

Fixed bushing

Rough material bushing

Rough material bushing Chip conveyor + bucket

Chip conveyor + bucket

Machine Specifications:

| ITEM | DIAMOND 12CSBIV | DIAMOND 20CSBIV | |

|---|---|---|---|

| Working Range | Max. machining dia. | Ø12.7 mm | Ø20 mm |

| Max. machining length per chucking | 150 mm | 150 mm | |

| Max. drilling dia. (main spindle) | Ø7 mm | Ø10 mm | |

| Max. drilling dia. (sub- spindle) | Ø7 mm | Ø7 mm | |

| Max. tapping dia. (main spindle) | M6 | M8 | |

| Max. tapping dia. (sub- spindle) | M6 | M6 | |

| O.D. Tooling | Number of tools | 6 | 6 |

| Dimension | □12 x 12 x 120 | □12 x 12 x 120 | |

| I.D. Tooling | Number of tools | 4 | 4 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | |

| Cross Working Driven Tooli |

Number of tools | 4 | 4 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | |

| Speed | 200~6000 rpm | 200~6000 rpm | |

| Front Working Driven Tooling |

Number of tools | 3 | 3 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | |

| Speed | 200~6000 rpm | 200~6000 rpm | |

| Back I.D Tooling | Number of tools | 4 | 4 |

| Dimension | 10 mm (ER16) / Ø20 mm | 10 mm (ER16) / Ø20 mm | |

| Main Spindle | Spindle hole dia. | Ø13 mm | Ø22 mm |

| Spindle speed | 200~8000 rpm | 200~8000 rpm | |

| Main spindle indexing angle | C 軸 | C 軸 | |

| Sub-Spindle | Spindle hole dia. | Ø13 mm | Ø22 mm |

| Spindle speed | 200~8000 rpm | 200~8000 rpm | |

| Max. length for front ejection | 50 mm | 50 mm | |

| Sub-spindle indexing angle | C axes | C axes | |

| Rapid Traverse | X1,Y1,Z1 axes | 30 M / MIN | 30 M / MIN |

| X2,Z2 axes | 15 M / MIN | 15 M / MIN | |

| Motors | Spindle motor | 2.2 kW | 2.2 kW |

| Sub-spindle motor | 2.2 kW | 2.2 kW | |

| X1,Y1,Z1,X2,Z2 axes motor | 1 kW | 1 kW | |

| Coolant pump motor | 1 HP | 1 HP | |

| Lubrication motor | 4 W | 4 W | |

| Driven tools motor | 1.5 kW | 1.5 kW | |

| Machine Dimensions |

Center height | 890 mm | 890 mm |

| Weight | 2150 kg | 2180 kg | |

| Machine dimension | 2500 x 1380 x 1800 mm | 2500 x 1380 x 1800 mm | |

| Air Pressure | Air pressure | 5 kg/cm | 5 kg/cm |

| Air supply | 10 L/min | 10 L/min | |