Introduction

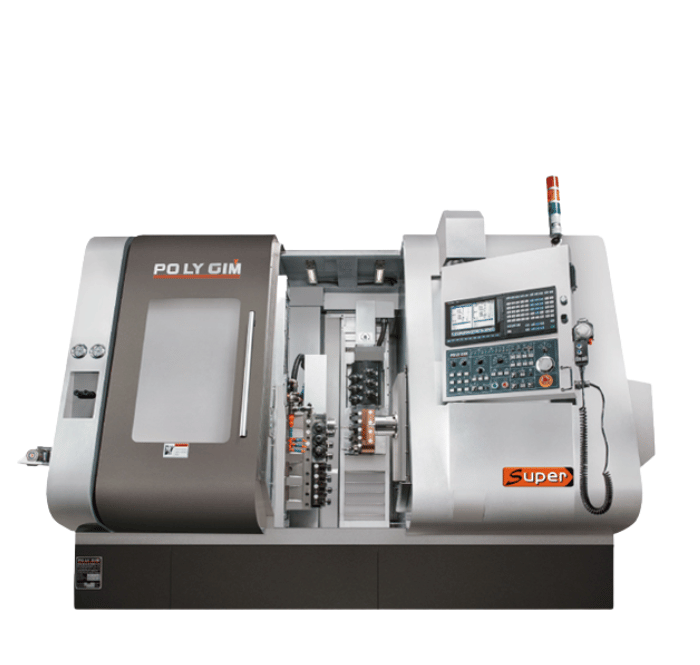

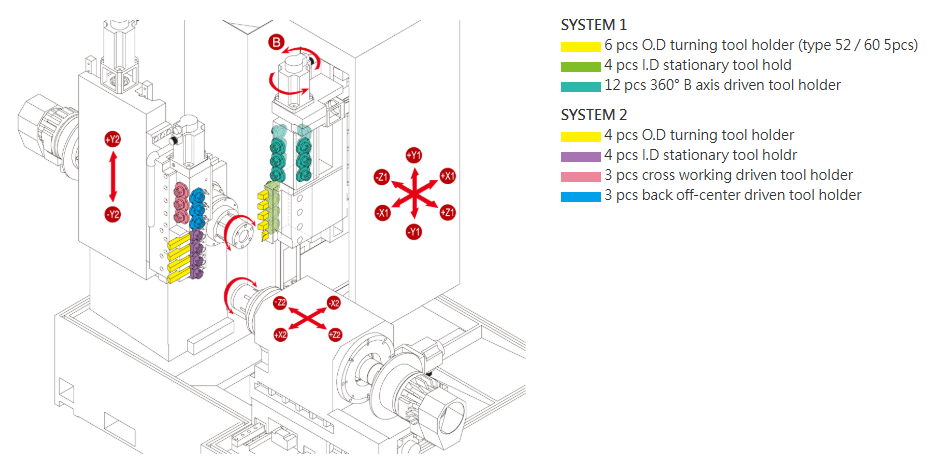

The SUPER CSL from Po Ly Gim is a multitasking turning center designed for Turning/milling operations. In addition to equip with various tool holders to meet versatile machining requirements, this machine is also designed with main and sub-spindle that allow any complicated part to be accomplished with only one setup.

Specification

| Items | Super CSL 42 System1 | Super CSL 42 System2 | Super CSL 52 System1 | Super CSL 52 System2 | Super CSL 60 System1 | Super CSL 60 System2 |

|---|

| Working Range |

|---|

| Max. Machining Dia. | Ø42mm | Ø42mm | Ø52mm | Ø52mm | Ø60mm | Ø60mm |

| Max. Machining Length | part diameter x 3 | | part diameter x 3 | | part diameter x 3 | |

| Max. Drilling Capacity | Ø30mm | Ø30mm | Ø30mm | Ø30mm | Ø30mm | Ø30mm |

| Toolong System |

|---|

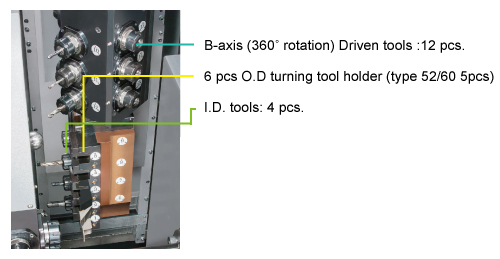

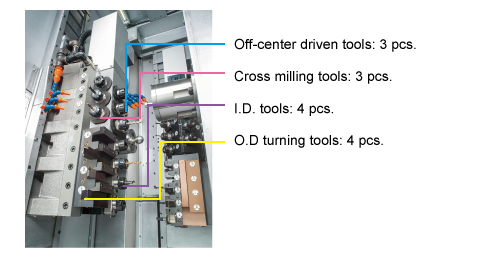

| O.D. Turning Tool | 6 | 4 | 5 | 4 | 5 | 4 |

| O.D. Turning Tool Dimension | □20x20x100 | □20x20x100 | □25X25X100 | □25X25X100 | □25X25X100 | □25X25X100 |

| I.D. Tool | 4 | 4 | 4 | 4 | 4 | 4 |

| I.D. Tool Dimension | Ø25mm | Ø25mm | Ø25mm | Ø25mm | Ø25mm | Ø25mm |

| Cross Tool (power – driven tool) | | 3 | | 3 | | 3 |

| Cross Tool Dimension | | 16mm (ER25) | | 16mm (ER25) | | 16mm (ER25) |

| Cross Tool Speed | | 200~6000rpm | | 200~6000rpm | | 200~6000rpm |

| Off-center driven Tool | | 3 | | 3 | | 3 |

| Off-center driven Tool Dimension | | 16mm (ER25) | | 16mm (ER25) | | 16mm (ER25) |

| Off-center driven Tool Speed | | 200~6000rpm | | 200~6000rpm | | 200~6000rpm |

| 360° Automatic Rotary Driven Tool | 12 | | 12 | | 12 | |

| 360° Automatic Rotary Driven Tool Dimension | 16mm (ER25) | | 16mm (ER25) | | 16mm (ER25) | |

| 360° Automatic Rotary Driven Tool Speed | 200~5000rpm | | 200~5000rpm | | 200~5000rpm | |

| Spindle |

|---|

| Spindle Hole Dia. | Ø46mm | | Ø60mm | | Ø65mm | |

| Spindle speed | 100~6000rpm | | 100~4000rpm | | 100~3000rpm | |

| Sub-spindle |

|---|

| Sub-spindle Hole Dia. | | Ø46mm | | Ø60mm | | Ø65mm |

| Sub-spindle Speed | | 100~6000rpm | | 100~4000rpm | | 100~3000rpm |

| Sub-spindle Max. Drilling Dia. | | Ø30mm | | Ø30mm | | Ø30mm |

| X1, Y1, Z1 axes | 20m/min | | 20m/min | | 20m/min | |

| X2, Y2, Z2 axes | | 20m/min | | 20m/min | | 20m/min |

| Motors |

|---|

| Main Spindle | 7.5/11 kW | | 11/15 kW | | 11/15 kW | |

| Sub-spindle | | 7.5/11 kW | | 11/15 kW | | 11/15 kW |

| Y1, Y2 axes | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW | 2.2 kW |

| X1, X2, Z1, Z2 axes | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW | 1.5 kW |

| B axes | 1 kW | | 1 kW | | 1 kW | |

| Rotary Tools | 4 kW | 4 kW | 4 kW | 4 kW | 4 kW | 4 kW |

| Coolant Pump | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP |

| Lubrication | 25w | 25w | 25w | 25w | 25w | 25w |

| Machine Dimensions |

|---|

| Center Height | 1125 mm | 1125 mm | 1125 mm | 1125 mm | 1125 mm | 1125 mm |

| Weight | 8300 kgs | 8300 kgs | 8400 kgs | 8400 kgs | 8500 kgs | 8500 kgs |

| Dimension | 2900x2330x2270 mm | 2900x2330x2270 mm | 2900x2330x2270 mm | 2900x2330x2270 mm | 2900x2330x2270 mm | 2900x2330x2270 mm |

| Dimension (with chip conveyor) | 3850x2330x2270 mm | 3850x2330x2270 mm | 3850x2330x2270 mm | 3850x2330x2270 mm | 3850x2330x2270 mm | 3850x2330x2270 mm |

| Air |

|---|

| Air Pressure | 5kg/cm | 5kg/cm | 5kg/cm | 5kg/cm | 5kg/cm | 5kg/cm |

| Air Supply | 10L/min | 10L/min | 10L/min | 10L/min | 10L/min | 10L/min |

* We reserve the rights to change the design without any prior notification.