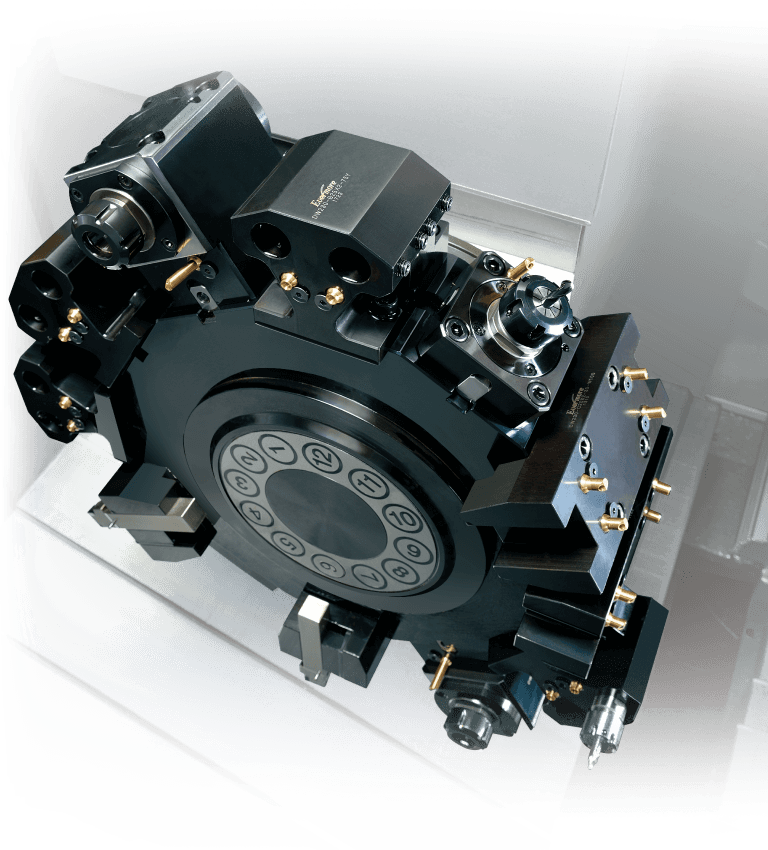

CSL 42-2Y II

Swiss Type CNC Lathe

Diamond CSL Series

Machine Features:

Diamond CSL 42-2YII is upgraded with MITSUBISHI 830 controller which possessed control axis superimposition function. It offers up to 10 axes complex manufacturing capability and it can simultaneously to process at 3 channels.

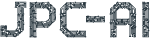

12 Stations Power Turret Can Do Double-side Processing

Main and Sub-Spindle are up to 42mm with 12 station power turret. Both built-in spindle are with MP Scale’s CS axis construction. This helps to obtain higher spindle rotation accuracy and better surface finish during cutting operation.

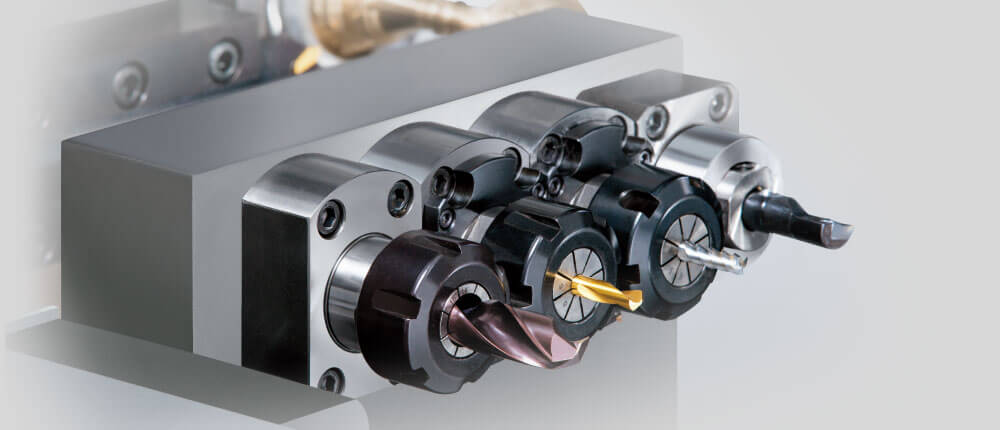

4 pcs Cross Working Driven Tool Holder

4 pcs Back Working Driven Tool Holder ( for 42-2Y II )

5 pcs O.D. Turning Tool Holder

Standard Accessories:

Main spindle

Main spindle Sub-spindle

Sub-spindle CS Axis (0.01° orientation)

CS Axis (0.01° orientation) Working Light

Working Light Coolant System

Coolant System Part off Detective Sensor

Part off Detective Sensor Live Bushing

Live Bushing Chip Conveyer

Chip Conveyer Chip Bucket

Chip Bucket

Part Catcher

Part Catcher 5 pcs O.D. Turning Tool Holder

5 pcs O.D. Turning Tool Holder 4 pcs Cross Working Driven Tool Holder

4 pcs Cross Working Driven Tool Holder 4 pcs Double Side Turning Holder (Turret)

4 pcs Double Side Turning Holder (Turret) 4 pcs Double Boring Bar Holder (Turret)

4 pcs Double Boring Bar Holder (Turret) 2 pcs Axial Drilling and Milling Head (Turret)

2 pcs Axial Drilling and Milling Head (Turret) 2 pcs Radial Drilling and Milling Double Head (Turret)

2 pcs Radial Drilling and Milling Double Head (Turret) 4 pcs Back Working DrivenTool Holder

4 pcs Back Working DrivenTool Holder Rough Material Bushing(Max. Machining = Bar Diameter x 3)

Rough Material Bushing(Max. Machining = Bar Diameter x 3)

Optional Accessories for Power Turret:

Double Side Turning Holder

Double Side Turning Holder Double Boring Bar Holder

Double Boring Bar Holder

Axial Drilling And Milling Head

Axial Drilling And Milling Head Radial Drilling And Milling Double Head

Radial Drilling And Milling Double Head

Machine Specifications:

| Items | Y1 (System 1) | Y2 (System 2) | (System 3) | |

|---|---|---|---|---|

| Working Range | Max. Machining Dia. | Ø42 mm | Ø42 mm | |

| Max. Machining Length | 280 mm | |||

| Max. Drilling Capacity | Ø30 mm | Ø30 mm | ||

| Max. Tapping Capacity | M16 | M16 | ||

| Tooling System | O.D. Turning Tool | 5 | ||

| O.D. Turning Tool Dimension | □20 x 20 x 120 | |||

| Cross Tool (Power - Driven Tool) | 4 | |||

| Cross Tool Dimension | 16 mm (ER25) | |||

| Cross Tool Speed | 200~6000 r.p.m. | |||

| Back I.D. Tool | 4 | |||

| Back I.D. Tool Dimension | Ø25 mm | |||

| Back Working Driven Tool | 4 | |||

| Back Working Driven Tool Dimension | 16 mm (ER25) | |||

| Back Working Driven Tool Speed | 200~6000 r.p.m. | |||

| Power Turret | Power-Driven Tool / Station | 12 | ||

| O.D. Tool Dimension | □20 x 20 | |||

| I.D. Tool Dimension | Ø25 mm | |||

| Max. O.D. Turning Tool / Station | 6 | |||

| Max. I.D. Bore Tool / Station | 6 | |||

| Power-driven Tool Dimension | 16 mm (ER25) | |||

| Power-driven Tool Speed | 200~4000 r.p.m. | |||

| Max. Radial Mill / Drill Tool / Station | 12 | |||

| Max. Axial Mill / Drill Tool / Station | 12 | |||

| Spindle | Spindle Hole Dia. | Ø42 mm | ||

| Spindle Speed | 200~6000 r.p.m. | |||

| Sub-spindle | Sub-Spindle Hole Dia. | Ø42 mm | ||

| Sub-Spindle Speed | 200~6000 r.p.m. | |||

| Max. Length for Front Ejection | 120mm | |||

| Sub-Spindle Max. Drilling Dia. | Ø30mm | |||

| Sub-Spindle Max. Tapping Dia. | M16 | |||

| Rapid Traverse Speed | X1, Z1, Y1, X2, Z2, Y2, X3, Z3 Axes | 30 m/min | 30 m/min | 30 m/min |

| Travel | X1 Axis | 45 mm | ||

| Z1 Axis | 300 mm | |||

| Y1 Axis | 360 mm | |||

| X2 Axis | 130 mm | |||

| Z2 Axis | 430 mm | |||

| Y2 Axis | 185 mm | |||

| X3 Axis | 245 mm | |||

| Z3 Axis | 450 mm | |||

| Motors | Main / Sub-Spindle | 7.5 kw | 7.5 kw | |

| Y1, Y2 Axes | 1.5 kw | 2.2kw | ||

| X1, Z1, X2, Z2, X3, Z3 Axes | 1.0 kw | 1.0 kw | 1.0 kw | |

| Rotary Tools | 2.2 kw | 2.2 kw | 2.2 kw | |

| Coolant Pump | 1 HP | 1 HP | ||

| Machine Dimensions | Lubrication | 25 W | 25 W | |

| Center Height | 990 mm | |||

| Weight | 6480 kgs | |||

| Air Pressure | Dimension | 3600 x 2650 x 2130 mm | ||

| Air Pressure | 5 kg / cm | |||

| Air Supply | 10 L / min | |||