SUPER CSL

CNC Lathe

Machine Features:

The SUPER CSL from Poly Gim is a multitasking turning center designed for Turning/milling operations. In addition to equip with various tool holders to meet versatile machining requirements , this machine is also designed with main and sub-spindle that allow any complicated part to be accomplished with only one setup.

Twin Y-axes design.

Twin Y-axes design. B-axis can be rotated 360˚ to perform any degree of drilling, tapping and milling operations.

B-axis can be rotated 360˚ to perform any degree of drilling, tapping and milling operations. B-axis rotation is driven by a servo motor, providing high indexing accuracy of 0.001˚.

B-axis rotation is driven by a servo motor, providing high indexing accuracy of 0.001˚. Main and sub-spindle speed : 3,000 rpm.

Main and sub-spindle speed : 3,000 rpm. Through hole diameter of main and sub-spindle:Ø65 mm.

Through hole diameter of main and sub-spindle:Ø65 mm. Both main and sub-spindle have Cs-axes function for performing contour machining.

Both main and sub-spindle have Cs-axes function for performing contour machining. All moving axes are mounted with heavy duty, roller type linear motion guides.

All moving axes are mounted with heavy duty, roller type linear motion guides. Fixed type spindle structure.

Fixed type spindle structure. The machine base is manufactured from high quality cast iron, tempered and stress relieved to eliminate structural deformation problems.

The machine base is manufactured from high quality cast iron, tempered and stress relieved to eliminate structural deformation problems.

Tooling System:

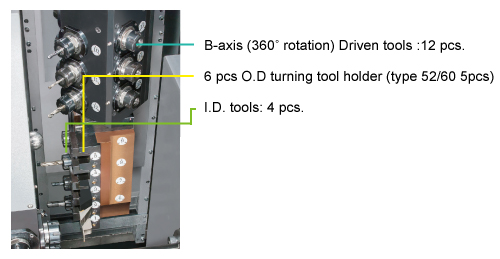

Tooling System for main Spindle

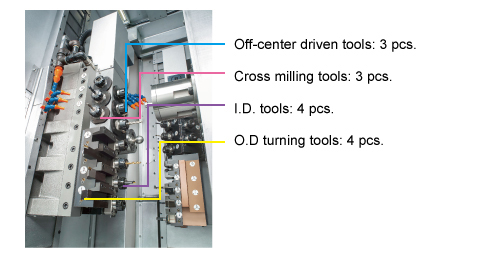

Tooling System for Sub-spindle

SYSTEM 1

6 pcs O.D turning tool holder (type 52 / 60 5pcs)

6 pcs O.D turning tool holder (type 52 / 60 5pcs)

4 pcs I.D stationary tool hold

4 pcs I.D stationary tool hold

12 pcs 360° B axis driven tool holder

12 pcs 360° B axis driven tool holder

SYSTEM 2

4 pcs O.D turning tool holder

4 pcs O.D turning tool holder

4 pcs I.D stationary tool holdr

4 pcs I.D stationary tool holdr

3 pcs cross working driven tool holder

3 pcs cross working driven tool holder

3 pcs back off-center driven tool holder

3 pcs back off-center driven tool holder

Standard Accessories:

Main spindle

Main spindle Sub-spindle

Sub-spindle CS axis orientation for both spindle

CS axis orientation for both spindle Working Light

Working Light Coolant System

Coolant System Part off Detective Sensor

Part off Detective Sensor Part Catcher

Part Catcher Spindle Coolant Device

Spindle Coolant Device

- System 1

6 pcs O.D turning tool holder (type 52 / 60 5pcs)

6 pcs O.D turning tool holder (type 52 / 60 5pcs) 4 pcs I.D. Stationary Tool Holder

4 pcs I.D. Stationary Tool Holder 12 pcs 360° Automatic Rotary Driven Tool Holder

12 pcs 360° Automatic Rotary Driven Tool Holder

- System 2

4 pcs O.D. Turning Tool Holder

4 pcs O.D. Turning Tool Holder 4 pcs I.D. Stationary Tool Holder

4 pcs I.D. Stationary Tool Holder 3 pcs Cross Working Driven Tool Holder

3 pcs Cross Working Driven Tool Holder 3 pcs Off-center Working Driven Tool Holder

3 pcs Off-center Working Driven Tool Holder

Option Accessories:

Chip Conveyer + Bucket

Chip Conveyer + Bucket Fedek Bar Feeder DH65L ( 1.5M)

Fedek Bar Feeder DH65L ( 1.5M)

Oil Coolant Device

Oil Coolant Device

Machine Specifications:

| Items | SUPER CSL 42 | SUPER CSL 42 | |

|---|---|---|---|

| SYSTEM 1 | SYSTEM 2 | ||

| Working Rang | Max. Machining Dia. | Ø42mm | Ø42mm |

| Max. Machining Length | part diameter x 3 | ||

| Max. Drilling Capacity | Ø30mm | Ø30mm | |

| Toolong System | O.D. Turning Tool | 6 | 4 |

| O.D. Turning Tool Dimension | □20x20x80 | □20x20x80 | |

| I.D. Tool | 4 | 4 | |

| I.D. Tool Dimension | Ø25mm | Ø25mm | |

| Cross Tool (power – driven tool) | 3 | ||

| Cross Tool Dimension | 16mm (ER25) | ||

| Cross Tool Speed | 200~6000rpm | ||

| Off-center driven Tool | 3 | ||

| Off-center driven Tool Dimension | 16mm (ER25) | ||

| Off-center driven Tool Speed | 200~6000rpm | ||

| 360° Automatic Rotary Driven Tool | 12 | ||

| 360° Automatic Rotary Driven Tool Dimension | 16mm (ER25) | ||

| 360° Automatic Rotary Driven Tool Speed | 200~6000rpm | ||

| Spindle | Spindle Hole Dia. | Ø46mm | |

| Spindle speed | 100~6000rpm | ||

| Sub-spindle | Sub-spindle Hole Dia. | Ø46mm | |

| Sub-spindle Speed | 100~6000rpm | ||

| Sub-spindle Max. Drilling Dia. | Ø30mm | ||

| X1, Y1, Z1 axes | 20m/min | ||

| X2, Y2, Z2 axes | 20m/min | ||

| Motors | Main Spindle | 7.5/11 kw | |

| Sub-spindle | 7.5/11 kw | ||

| Y1, Y2 axes | 2.2 kw | 2.2 kw | |

| X1, X2, Z1, Z2 axes | 1.5 kw | 1.5 kw | |

| B axes | 1 kw | ||

| Rotary Tools | 4 kw x 2 | ||

| Coolant Pump | 1 HP | 1 HP | |

| Lubrication | 25w | 25w | |

| Machine Dimensions | Center Height | 1125 mm | |

| Weight | 7300 kgs | ||

| Dimension | 2900x2330x2270 mm | ||

| Dimension (with chip conveyor) | 3850x2330x2270 mm | ||

| Air | Air Pressure | 5kg/cm | |

| Air Supply | 10L/min | ||

| Items | SUPER CSL 52 | SUPER CSL 52 | |

|---|---|---|---|

| SYSTEM 1 | SYSTEM 2 | ||

| Working Rang | Max. Machining Dia. | Ø52mm | Ø52mm |

| Max. Machining Length | part diameter x 3 | ||

| Max. Drilling Capacity | Ø30mm | Ø30mm | |

| Toolong System | O.D. Turning Tool | 5 | 4 |

| O.D. Turning Tool Dimension | □25X25X80 | □25X25X80 | |

| I.D. Tool | 4 | 4 | |

| I.D. Tool Dimension | Ø25mm | Ø25mm | |

| Cross Tool (power – driven tool) | 3 | ||

| Cross Tool Dimension | 16mm (ER25) | ||

| Cross Tool Speed | 200~6000rpm | ||

| Off-center driven Tool | 3 | ||

| Off-center driven Tool Dimension | 16mm (ER25) | ||

| Off-center driven Tool Speed | 200~6000rpm | ||

| 360° Automatic Rotary Driven Tool | 12 | ||

| 360° Automatic Rotary Driven Tool Dimension | 16mm (ER25) | ||

| 360° Automatic Rotary Driven Tool Speed | 200~6000rpm | ||

| Spindle | Spindle Hole Dia. | Ø60mm | |

| Spindle speed | 100~6000rpm | ||

| Sub-spindle | Sub-spindle Hole Dia. | Ø60mm | |

| Sub-spindle Speed | 100~6000rpm | ||

| Sub-spindle Max. Drilling Dia. | Ø30mm | ||

| X1, Y1, Z1 axes | 20m/min | ||

| X2, Y2, Z2 axes | 20m/min | ||

| Motors | Main Spindle | 7.5/11 kw | |

| Sub-spindle | 7.5/11 kw | ||

| Y1, Y2 axes | 2.2 kw | 2.2 kw | |

| X1, X2, Z1, Z2 axes | 1.5 kw | 1.5 kw | |

| B axes | 1 kw | ||

| Rotary Tools | 4 kw x 2 | ||

| Coolant Pump | 1 HP | 1 HP | |

| Lubrication | 25w | 25w | |

| Machine Dimensions | Center Height | 1125 mm | |

| Weight | 7400 kgs | ||

| Dimension | 2900x2330x2270 mm | ||

| Dimension (with chip conveyor) | 3850x2330x2270 mm | ||

| Air | Air Pressure | 5kg/cm | |

| Air Supply | 10L/min | ||

| Items | SUPER CSL 60 | SUPER CSL 60 | |

|---|---|---|---|

| SYSTEM 1 | SYSTEM 2 | ||

| Working Rang | Max. Machining Dia. | Ø60mm | Ø60mm |

| Max. Machining Length | part diameter x 3 | ||

| Max. Drilling Capacity | Ø30mm | Ø30mm | |

| Toolong System | O.D. Turning Tool | 5 | 4 |

| O.D. Turning Tool Dimension | □25X25X80 | □25X25X80 | |

| I.D. Tool | 4 | 4 | |

| I.D. Tool Dimension | Ø25mm | Ø25mm | |

| Cross Tool (power – driven tool) | 3 | ||

| Cross Tool Dimension | 16mm (ER25) | ||

| Cross Tool Speed | 200~6000rpm | ||

| Off-center driven Tool | 3 | ||

| Off-center driven Tool Dimension | 16mm (ER25) | ||

| Off-center driven Tool Speed | 200~6000rpm | ||

| 360° Automatic Rotary Driven Tool | 12 | ||

| 360° Automatic Rotary Driven Tool Dimension | 16mm (ER25) | ||

| 360° Automatic Rotary Driven Tool Speed | 200~6000rpm | ||

| Spindle | Spindle Hole Dia. | Ø65mm | |

| Spindle speed | 100~3000rpm | ||

| Sub-spindle | Sub-spindle Hole Dia. | Ø65mm | |

| Sub-spindle Speed | 100~3000rpm | ||

| Sub-spindle Max. Drilling Dia. | Ø30mm | ||

| X1, Y1, Z1 axes | 20m/min | ||

| X2, Y2, Z2 axes | 20m/min | ||

| Motors | Main Spindle | 7.5/11 kw | |

| Sub-spindle | 7.5/11 kw | ||

| Y1, Y2 axes | 2.2 kw | 2.2 kw | |

| X1, X2, Z1, Z2 axes | 1.5 kw | 1.5 kw | |

| B axes | 1 kw | ||

| Rotary Tools | 4 kw x 2 | ||

| Coolant Pump | 1 HP | 1 HP | |

| Lubrication | 25w | 25w | |

| Machine Dimensions | Center Height | 1125 mm | |

| Weight | 7500 kgs | ||

| Dimension | 2900x2330x2270 mm | ||

| Dimension (with chip conveyor) | 3850x2330x2270 mm | ||

| Air | Air Pressure | 5kg/cm | |

| Air Supply | 10L/min | ||